- Home

- Latest News

- Thames Water’s wastewater treatment no longer running at a snail’s pace

Thames Water’s wastewater treatment no longer running at a snail’s pace

Slough Wastewater Treatment Works is one of Thames Water’s largest treatment plants, serving a population of 250,000. In 2016, the facility was being regularly disrupted by snail shells creating serious operational problems. The problem was easily solved by modifying the backwash system of three existing Hydrotech® Discfilters; costs will be recovered by 2018 and snail shell blockages have become a thing of the past.

Infestations of sewage snails have become a widespread problem in the wastewater treatment industry, affecting operational continuity and creating sedimentation problems downstream. Paradoxically, the continued improvements to process treatment technologies that are helping industry and the environment are also creating an ideal habitat for the snails. This is leading to pump and equipment damage from the abrasive grit formed from broken down shells, and affecting productivity. At the same time, the release of shell fragments into the receiving water course is also affecting compliance with Environment Agency standards.

The Slough Wastewater Treatment Works has recently experienced this common nature-based challenge first hand. For over 10 years he plant has invested heavily in improving its works to great success – using on-site sludge digestion to produce biogas and achieving 65 % self-sufficiency in energy use – increasing efficiency and protecting the River Boveney where the final effluent discharges.

Unfortunately, the combination of low pollutant levels, higher dissolved oxygen, warm water and nutrients created by these essential improvements provided the perfect habitat for sewage snails and, by 2016, the infestation had become a major nuisance at the plant. The snail shells were causing serious operational problems right through the process – within aeration basins, secondary clarifiers and tertiary treatments – and a solution had to be found. The prospect of removing the shells from the treatment process would be a costly and labour-intensive exercise, likely to require major maintenance and even a works shut down. Thames Water’s Performance Manager Andy Moore approached Veolia Water Technologies for help. Veolia engineers soon identified the cause of the problem, and came up with much easier solution.

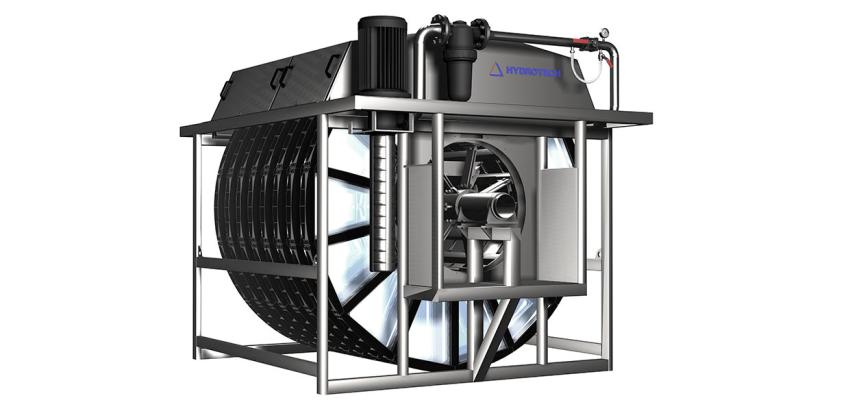

In 2005, as part of the original investment programme, the plant had installed three Hydrotech Discfilters from Veolia to improve the quality of the final effluent. This addition proved to be not only cost effective but also sustainable, providing lower backwash water volumes – around 13 % of throughput – reduced power consumption and minimum maintenance compared with competing technologies. A simple modification to the backwash system of the three Discfilters – retrofitting new self-cleaning nozzles – avoided nozzle blockages, reduced strainer replacements and lowered maintenance. More importantly, it solved the problem of snail infestations. As a result, the plant is once again running to its optimum efficiency, and snail-related challenges are a thing of the past.

Thames Water is extremely pleased with the result, as Andy explained: “I estimate we will recover the cost of the modification in under two years and we have now added a fourth Discfilter –with the backwash system upgrade.”

The situation at the Slough plant is a prime example of Veolia understanding what its customers need to keep operations on track, whatever the circumstances, Veolia responds quickly. Keeping businesses running regardless of the water-related challenges they may face.