- Home

- Latest News

- RecoSMART Solution

RecoSMART Solution

Save Your Company Energy And Money With The RecoSMART System

Many companies often overlook the amount of energy that a poorly optimised boiler system will lose. This is why we have created the RecoSMART system of adaptive boiler water treatment chemicals as part of Reco solutions.

What Is RecoSMART And How Can It Aid Your Business? Veolia Water Technologies, as leading experts in boiler water treatment chemicals, developed RecoSMART for companies looking to avoid blowdown and to reduce their costs by optimising their boiler system. Boiler blowdown is detrimental to efficiency, and careful steps must be taken to prevent it.

What is blowdown? It consists of water, conditioning chemicals and heat energy often intentionally wasted from boilers. It is done to avoid the impurities concentrating during the continual evaporation of steam. Steam pressure then blows this water out of the boiler, which can be woefully inefficient. And your company will be paying the price.

The RecoSMART solution was created by Veolia Water technologies to tackle this. By improving the quality of the boiler feed water. Dealkalisation, water softening, reverse osmosis or deionisation can all help you reduce your blowdown and improve the energy efficiency of your boiler system. In the process, you'll be saving money too!

To find out which is more suitable for your requirements, we will conduct a detailed site survey and craft a RecoSMART solution to maximise your boiler system's performance.

How Has RecoSMART Helped Our Clients?

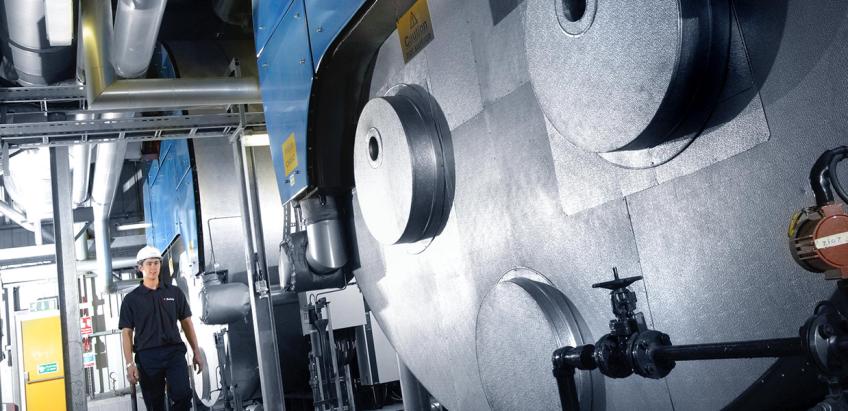

Let's take a look at a case study. A major energy recovery facility in Birmingham required a specialist supplier of boiler water treatment chemicals to help improve the efficiency of their boiler system.

The facility itself incinerates 350,000 tonnes of non-recyclable waste annually. In doing so, it generates 25MW of electricity which is exported to the national grid. The boiler system consists of two 45bar 400˚C tube boilers delivering 67 tonnes per hour of steam to high pressure turbines. There is also a 10bar waste steam heat shell boiler. This is fuelled by a clinical waste incinerator and supplies steam to a low pressure turbine.

Boiler efficiency in the facility is maximised by the careful control of all feed water. This is produced on site as high purity deionised water. Oxygen is scavenged and the pH level adjusted by the addition of boiler water treatment chemicals. In turn, this stops corrosion.

Because of the two types of boiler system, with the same common feed water and condensate systems means that the controlling the water chemistry required a specialist solution. By conducting a thorough site search, Veolia Water Technologies were able to develop a RecoSMART solution, which included Hydrex chemicals, to provide protection to the boilers, condensate system and turbines.

The facility's Operation managing was very pleased with the results, stating: "Veolia Water Technologies worked closely with us to achieve the appropriate boiler water quality and we've been particularly impressed with the technical support and their readiness to formulate bespoke conditioning chemicals for our system."

Learn More About RecoSMART Boiler Water Treatment Chemicals Today

To learn more about how the RecoSMART system can improve your company's boiler efficiency, contact us here at Veolia Water Technologies today. We have over 75 years experience in the creation of specialist boiler water treatment chemicals and other solutions designed to meet our client's exacting requirements.

To discuss how we can create your ideal water solution, or for more information please get in touch through our online contact page.