- Home

- Latest News

- Letting Off Steam

Letting Off Steam

Kate Wild of Veolia Water Technologies gets steamed up about boiler water treatment

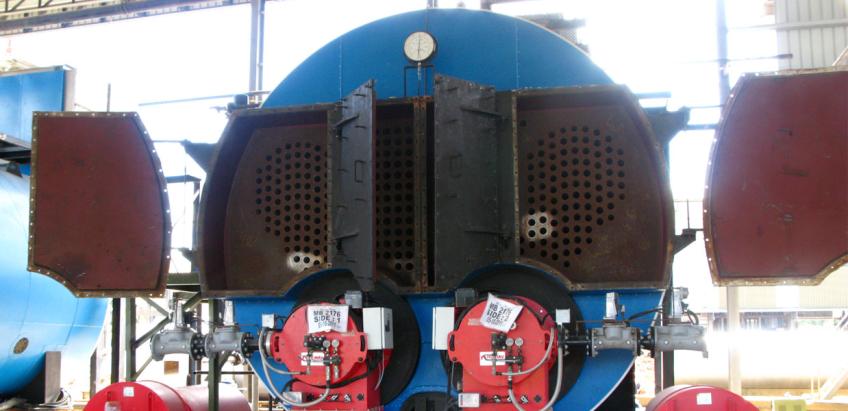

The humble packaged shell boiler is, arguably, the critical unit in the building when it comes to energy consumption and environmental pollution. Modern boilers use fuel efficiently and produce low emissions but if the resulting heat cannot be transferred into the boiler water efficiently, then the boiler will consume too much fuel, increasing both carbon footprint and operating costs. With heat transfer rates as high as 300kw/m2 any deposit on the water side of the heat transfer surface defeats the fire side efficiencies.

To ensure optimum waterside conditions, boiler feed water needs to be at least, softened, to remove calcium and magnesium salts which would otherwise lead to scale formation. It then has to be dosed with a variety of “conditioning chemicals” to remove oxygen, prevent corrosion and condition sludge. As water turns to steam in the boiler it leaves behind all the salts that were dissolved in the feedwater so the boiler water becomes more concentrated. To control the boiler water TDS (Total Dissolved Solids) to the maximum set by BS2486, some of the concentrated boiler water is discharged to sewer as “blowdown”. This blowdown water was originally purchased from the mains supply, treated in the make-up water treatment plant, dosed with expensive conditioning chemicals and heated to boiling point. When you add in the cost of mains water, fuel, chemicals and sewer disposal it probably costs at the very least about £3 per m3. Improving the make-up water treatment can reduce the volume that has to be dumped to drain thus saving money.

Maximising condensate return minimises the blowdown rate but it’s not always possible. Reducing the TDS of the make-up water by “external treatment” will also help to reduce blowdown. Consider a 20tph boiler with 40% condensate return and make-up from a 500mg/l TDS London mains water. A water softener will remove calcium and magnesium ions from the make-up water but will not reduce its TDS, so the blowdown will be about 2m3/h costing around £45,000 per annum. Treating the make-up water by reverse osmosis will reduce its TDS by about 95% and the blowdown would be less than 0.1m3/h saving over £40,000 per annum. The annual operating costs of the Reverse Osmosis (RO) plant would be in the region of £15,000 giving a net saving of roughly £25,000 per annum and a payback of about 12 months. Veolia Water Technologies (Veolia) has developed an online tool called recoSMART to evaluate the potential cost savings resulting from alternative external treatment options.

Equally important is internal treatment or chemical conditioning to control the boiler water chemistry. This needs a number of chemical additives – typically scale inhibitors, dispersants, oxygen scavengers and steam line treatments and ensuring that their concentrations are correct is critical to efficient operation. Under-dosing exposes the boiler to potential scaling and corrosion problems whilst over-dosing wastes money and with some chemicals, can cause corrosion. Veolia’s range of water treatment chemicals includes both organic and inorganic chemicals formulated to meet the individual customer’s needs, and is supported by automatic control systems and regular site visits by Veolia’s service technicians.

Typical of Veolia’s customers is Bristol Royal Infirmary. In Bristol’s boilerhouse, make-up water is treated by softening and RO and mixes with returned condensate in the hotwell. Chemicals are added to provide oxygen scavenging and pH adjustment for corrosion inhibition together with a polymer for sludge conditioning. Veolia’s AQUAService contract not only provides the supply of chemicals together with a programme of fortnightly visits, by a chemical technician, to carry out chemical testing and dosing adjustment to optimise boiler conditions, but also a biannual full servicing of the water softener and RO plant, which is now operating more efficiently and is generating savings by reducing both blowdown and usage of chemicals.

Visit www.recosolutions.co.uk to find out how you can reduce costs by improving boiler efficiency.