Hubgrade for the Food & Beverage market

Maintaining a stable and compliant water treatment process

Both food and beverage production need a sustainable supply of water. With compliance and process water treatment constant priorities, factories must embrace digital technology like Hubgrade to meet performance targets and reduce costs.

F&B manufacturers face many challenges

Unlike other factories, food and beverage companies can have many different products to make, each requiring different volumes of process water. It’s just one added challenge for factory managers where water monitoring and treatment is concerned.

Being able to make informed decisions using real-time data and predictions from machine learning is incredibly valuable. Harnessing the internet of things (IoT), you can optimise your systems, resulting in countless efficiencies.

Typical water challenges for food and beverage producers:

- Maximising uptime and stability of equipment

- Monitoring wastewater composition

- Ensuring compliance

- Reducing operating costs

- Increasing efficiency from existing equipment

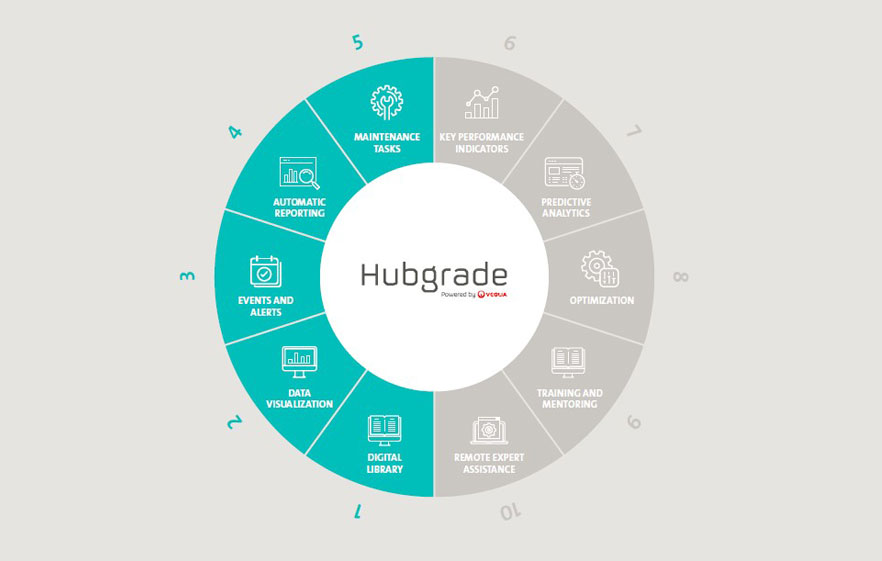

How Hubgrade can help

Accessed remotely, 24/7, Hubgrade Essential gives you complete and real-time visibility of your water treatment equipment. From one dashboard, find everything you need to optimise your system. You will also avoid costly downtime by setting tailored alarms to highlight issues early. Hubgrade Performance can optimise your effluent treatment plant in real time to ensure stable operation, maximise asset capacity, reduce operational time, and ensure compliance.